A heavy mixed hardwood table to use as a working table for any projects demanding a firm elevated surface or as a dinner table for four chairs. The table top is made from recuperated canela wood from the highly damaged door frames and window frames we removed in the apartment, assembled with floating tenons and dowels.

The mitred apron is made from street-sourced hardwood. The legs are bulletwood from a leftover roofing beam, connected by stretchers made of unknown hardwood (recovered from an old roof structure) and then connected with a bulletwood central stretcher (from leftover rafters), both with mortise and tenon joints. I added diagonal bulletwood braces to prevent any racking and further enhance stability. These braces are inserted into grooves carved on baseplates mounted on the underside of the table top and then slid sideways into position under high tension, pushing against each other in a shallow notch in the middle of the central stretcher to be well-tensioned and easy to unmount.

Due to the density and hardness of the bulletwood, it was very difficult to do any fine work on it besides slight adjustments. Therefore, I decided to have the tabletop simply slot onto the legs. The slots are between the apron-tabletop structure and bulky triangular blocks screwed underneath and then to the legs, making it possible to unscrew and remove the whole tabletop/apron structure from the base structure for considerably easier transport of the heavyweight piece.

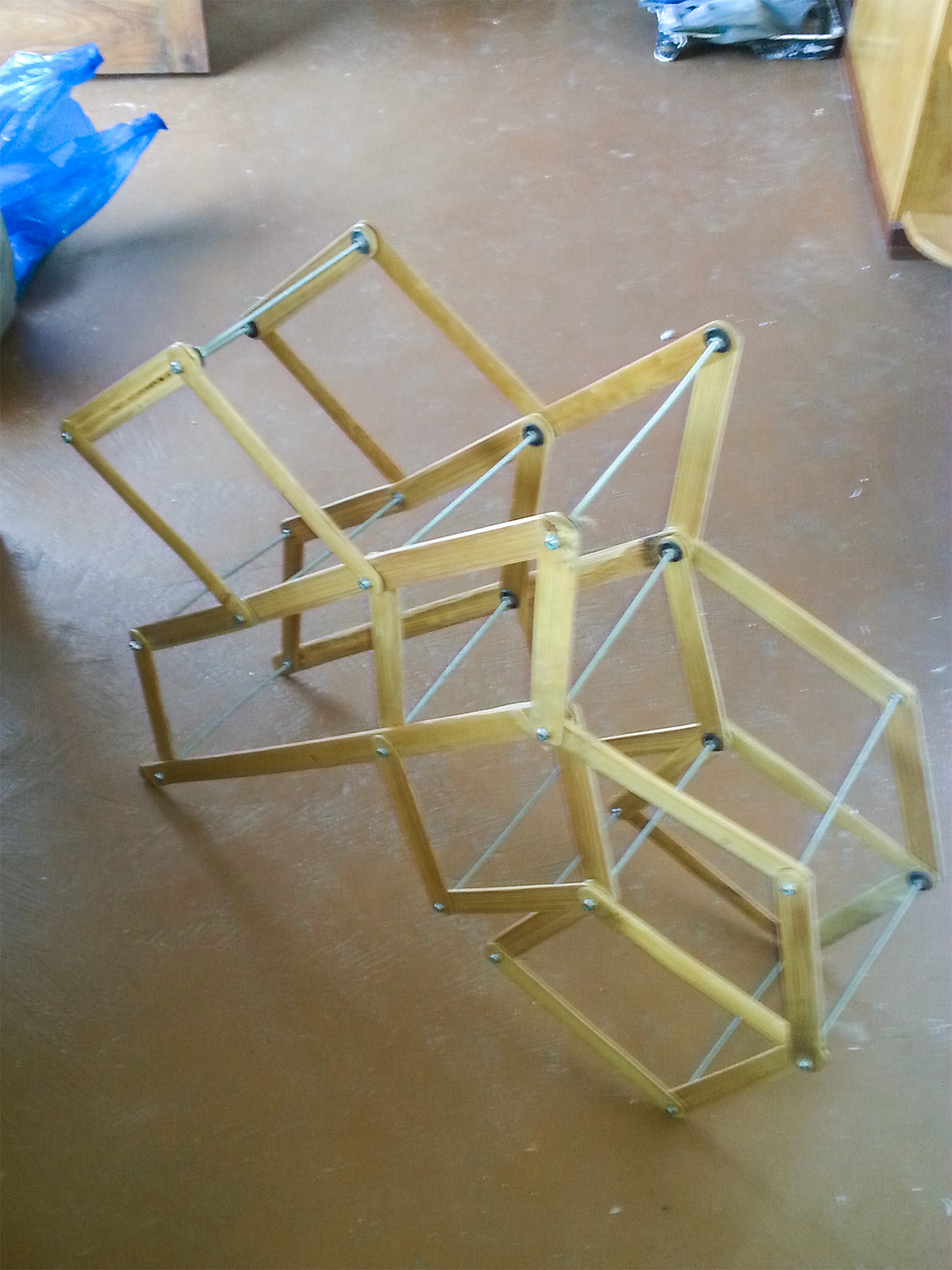

This trestle-like structure serves as a support for a temporary table or workbench. It features two crossed frames that are collapsible due to central pins with butterfly nuts on both sides. Chains are used to control the degree of opening, thereby adjusting the table's height. For enhanced stability and longevity, the frames are build with mortise and tenon joints. The wood used is moulding pieces from old doorways, made of lighter canela wood (brazilian sassafras).

After raising the wall height with a reinforced concrete beam, the timber framing was further elevated by a 20 cm high main beam, anchored on top of the wall and supporting 9 rafters secured with joints. The wood used is the beautiful maçaranduba (also known as bullet wood), one of the hardest (most dense) woods in the world, very durable and resistant to weather and bugs. The roofing material consists of white sandwich roof tiles, made of two metal sheets with polyurethane thermal insulation.

The timber and tile panels were by far the most expensive materials used in the renovation. The space's owner, a wealthy individual who let the property deteriorate for nearly four decades, agreed to cover only that part (the new roof extends to a small neighboring unit). So naturally we opted for the best quality available, and for what would make ar real difference in the thermal comfort of living in an air-conditioning-free penthouse in Brazil..

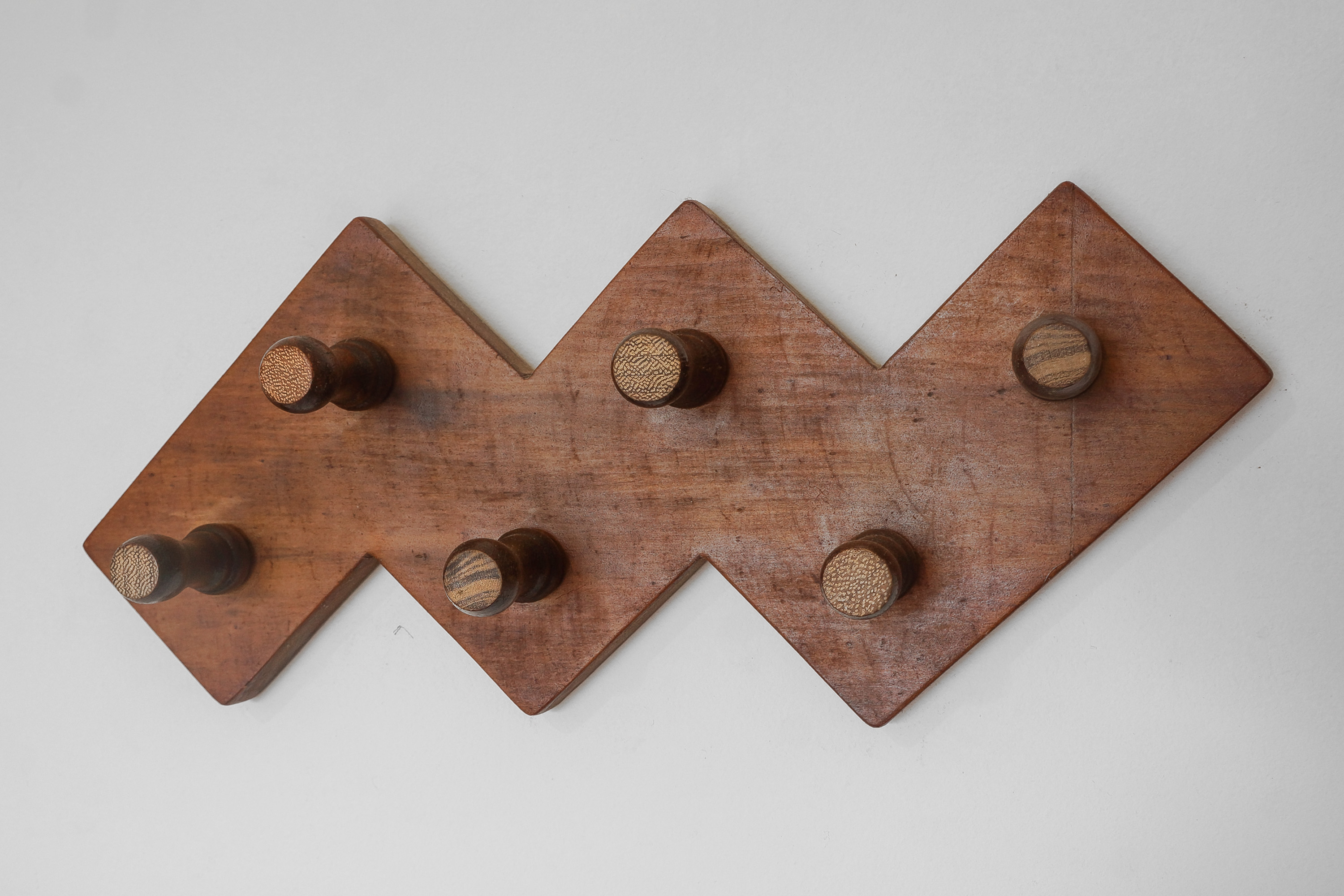

Coat or bag racks featuring backboards shapes cut from streetsourced softwood (non-pine) and pegs cut from turned hardwood pieces, revealing the end grain.

After being confronted with an absurd price for a plastic louvered door insert needed to improve ventilation, I decided to make a wooden one myself. Since I was working on several challenging projects, a quick DIY item like this can be somewhat relaxing and offers quick feedback.

My first furniture piece; made entirely from materials sourced on the streets of Niterói, RJ. It features a simple hardwood frame with corner brackets, an MDF bottom, a plywood top, HDF sidewalls, and a pine plank shelf. I found a piece with a groove cut and used it for inserting the thin sliding panels (HDF boards).

As with all my woodwork the dimensions and/or amount of the found/recovered wood pieces dictate the measures of the final object.

I found three legs of a stool. Since round wood pieces can be a rare find on the streets, I scraped the fourth leg and the stretchers from wood with square and rectangular cross-sections. The seat cut from a beautiful piece of Angelim Pedra (Angel's Heart) wood.

To achieve a darker wood finish on the water-resistant plywood board used for the ceiling of the shower box and the base for the water tank, I applied multiple layers of stain and varnish, resulting in a very satisfactory glazed effect that complements the bulletwood of the beams.

With more woodworking projects planned in this space, I reserved part of the room divider for my tool case and made a compartmentalized drawer to organize small hardware like bits and screws.

A mirror frame made from dark (aged) canela wood (Brazilian sassafras) was crafted from recovered molding pieces that were previously painted white (sic!), same as those used in the folding trestle.Back inserts for the mirror pane were made from plywood by removing layers of wood veneer to create rabbets.

Inspired by Ottoman stools, this low, sturdy, and heavy piece boasts a thick seat with a slight carve for added comfort. The seat is crafted from old rafters salvaged from the roof, sanded down, and glued together into a solid panel. Legs and stretchers are carved round from various pieces of found wood, with some parts glued and doweled together before carving to achieve the desired size and shape.

Finished with a lacquer containing a solar filter, the stool is prepared to withstand humid conditions in semi-open areas like terraces. However, this finish—like most solar filter-enhanced wood finishes—has given the wood a much warmer (somewhat yellowish) and darker tone, which I will try to avoid in the future.

A simple built-in closet, extending from floor to ceiling, inspired by the approach in Mario Dal Fabbro's book on built-in furniture. The closet's walls are constructed from repurposed construction planks, some nice hardwood pieces and light, well-fitted doorframes with a semi-transparent mesh fabric.

The semi-inbuilt floating shoerack features glazed plywood walls and back from a HDF pegboard for some airflow. It also functions as a small tabletop in the entryway.

The kitchen cabinet features a partly wall-mounted structure supported by peroba rosa wood legs, interlocked into a frame with robust castle joints (shiro joints). Atop the frame sits a custom concrete countertop with an integrated sink. Sliding doors from humidity-resistant plywood (leftovers from the watertank base), glide nicely in the cost-efficient double L-shaped aluminum drywall profiles. As do the drawers, made from pine wood with natural knot details.

An improvised kitchen (and there have been many in my life) needs a well-thought-out wall-mounted drying rack. The first one was a rather clumsy but fun piece made entirely of bamboo, a material that, when chemically treated, is remarkably resistant to water. The second rack was constructed from pallet wood and some thermally treated scrap pieces.